BOOST PRODUCTIVITY WITH NEW AND USED CNC STONE MACHINES

Is your shop leaking profits? Are manual processes taking too long? Is your shop experiencing inconsistent quality creating wasted materials? Are rising labor costs squeezing margins? Our CNC stone machines for sale increase productivity and profits

Automate With a CNC Stone Router Machine

Imagine the potential for your business with a CNC router for stone cutting. Here's what other shop owners found after adding automation:

- Machines are dependable and show up for work every day

- Machines deliver precision quality every time

- Machines multiply productivity

- Machines improve job satisfaction and employee retention

- Machines increase profitability

Types of CNC Router Machines for Stone Fabrication

Stone CNC routers come in various configurations, each designed for specific applications in stone fabrication.

- 3-Axis CNC Routers: Ideal for flat surface cutting, engraving, and shaping of marble, granite, and quartz. These machines are widely used for countertop fabrication and decorative engraving.

- 4-Axis CNC Routers: Provide added flexibility by allowing the spindle to tilt, enabling advanced edge profiling and curved surface cutting.

- 5-Axis CNC Routers: Offer full 3D machining capabilities, perfect for intricate carvings, statues, and complex stone designs. These machines excel in precision and versatility.

- CNC Operated Bridge Saws: Designed for cutting large stone slabs with high precision, often used in countertop and tile production.

Choosing the right CNC stone router depends on production needs, material type, and desired cutting complexity.

A CNC Stone Cutter Can Process the Following Materials:

- Granite

- Marble

- Limestone

- Quartz

- Slate

- Sandstone

- Travertine

- Onyx

- Soapstone

- Engineered Stone

CNC Marble Cutting Machine

A CNC marble cutting machine is equipped with a high-precision spindle and is widely used in the construction and decorative industries for creating intricate designs in marble for flooring, countertops, and artistic installations. This machine features a robust structure to handle the weight and abrasiveness of marble. It uses either a diamond-tipped saw blade or a water jet for cutting, depending on the specific model and application.

CNC Granite Cutting Machine

The CNC stone-cutting machine uses computer-controlled automation to cut granite precisely. It typically features a powerful cutting blade or laser, often diamond-tipped, for effective and precise cutting through hard granite. This is usually equipped with a water cooling system to prevent overheating and reduce dust during the cutting process.

CNC Quartz Cutting Machine

A CNC quartz cutting machine can perform a variety of cuts, from simple straight lines to complex shapes and contours, as per the programmed design. Safety features include emergency stops and protective guards. Discover efficiency and precision in stone processing with our CNC stone machines.

Investing in the Right New and Used Stone Machinery

Making an equipment investment can be a big decision. The right decision will provide a return on your investment. Anything else is just an expense.

For over 30 years, we've been helping shop owners select, purchase, and integrate manufacturing equipment that delivers a return on investment and helps them grow their business profitably.

We've created a checklist of questions to think about as you evaluate equipment choices for your shop. These are questions shop owners like you have asked when considering new equipment.

Download the Checklist

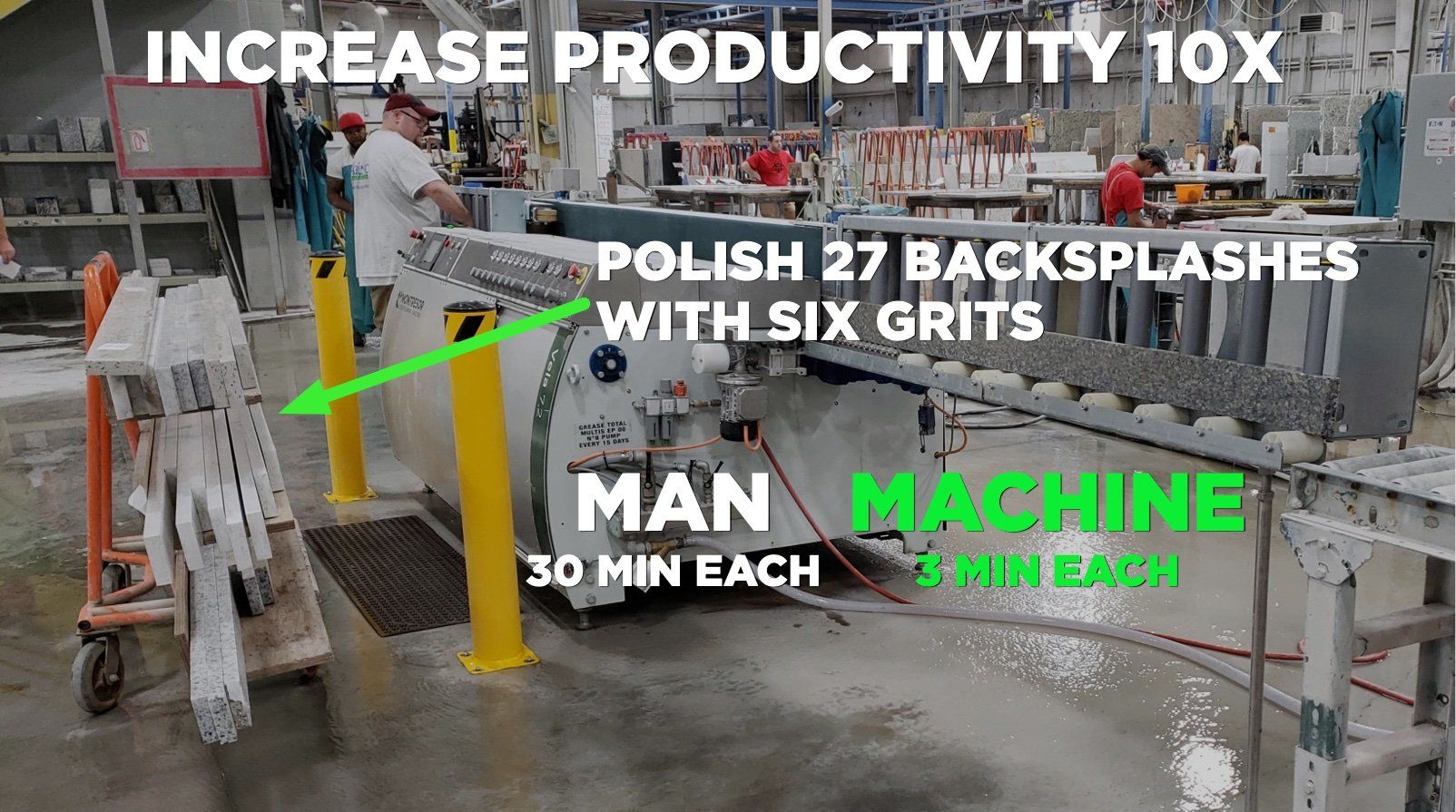

Stone Fabrication Increases Productivity 10x With Edge Polishing

Time and consistency are two of the biggest challenges stone fabricators face with manual polishing.

Chances are each of your workers has developed a different level of skill, often to the point where you can identify one person's work over another. That creates a quality problem.

One fabricator calculated that it took his employee 30 minutes to o polish a backsplash using six different grits manually. One project required 27 backsplashes, which would have taken over a day and a half to complete manually, not including breaks and lunches.

Instead, with the Montressor VELA 7.2 flat polishing machine for backsplashes, all 27 pieces were polished with six grits in under 90 minutes.

And, the polishing quality was identical on each piece.

Are you ready to get results like these?

With used CNC stone machines for sale, your shop can easily achieve faster project turnaround, increased customer satisfaction, more work, and higher profits.

One benefit the owner should have expected was his team's increased job satisfaction

The new equipment made their jobs easier and more satisfying, resulting in happier employees, reduced errors and accidents.

Contact Diversified Equipment and Supply today to see how our CNC stone machines can help your business.