Exploring the Benefits and Types of Vacuum Pumps for Woodworking and Stone Fabrication

Vacuum air systems are key in industrial woodworking and solid surface fabrication. Apart from their common uses like lifting and holding materials down on CNC machines, there are many types of vacuum pumps for woodworking and stone fabrication that improve efficiency, safety measures, and overall quality at different production stages. In this blog, we’ll discuss the role of vacuum systems in industrial woodworking and solid surface fabrication.

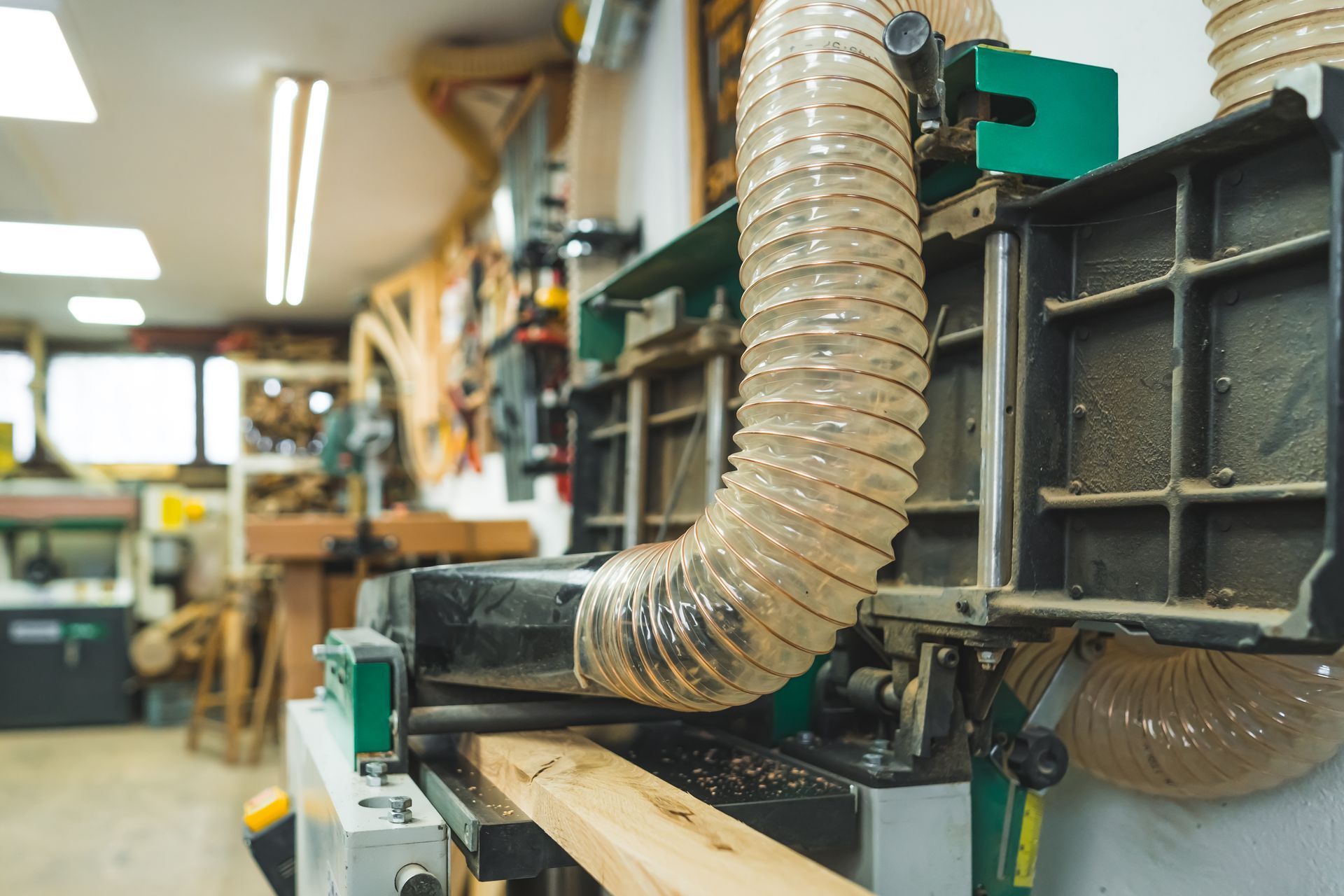

Dust Collection and Management

- Purpose: To remove dust and dirt made when you cut, sand, route, or do other machining.

- Details: Vacuum systems can be smoothly combined with dust collection arrangements to gather fine particles at the origin. This helps keep the work area cleaner and is also very important for lessening dust that flies through the air. It's also necessary for safety and product quality

- Benefits: Better quality of air, less risk of fire, following safety rules at work, and improved machine functioning by stopping dust from accumulating.

Material Handling and Transportation

- Purpose: Facilitate the movement of heavy or unwieldy materials within the shop or factory.

- Details: Vacuum lift systems are designed to handle large sheets of wood, solid material surfaces, and laminated panels. They help decrease the work done by hand, reduce the chances of getting hurt, and make processes from storage to machining stations much smoother.

- Benefits: Increased efficiency, reduced physical strain on workers, and faster material handling.

Clamping and Fixturing

- Purpose: Secure workpieces during manufacturing processes like gluing, assembling, or drilling.

- Details: Vacuum clamping systems can hold parts in position, avoiding marks or harm from mechanical clamps. This solution proves very useful for processes that demand precision and repetition.

- Benefits: It can do work with greater accuracy, setting up is fast, and the chances of damage are reduced.

Veneering and Laminating

- Purpose: Apply veneers or laminates to wood or other substrates.

- Details: Vacuum presses use negative air pressure to apply even force to the veneer or laminate surface, ensuring a uniform bond without air bubbles or empty spaces. This step is crucial to getting good finishes in cabinetry and furniture fabrication.

- Benefits: Better quality and uniformity when applying veneer and laminate, less chance of delamination, and improved surface finish.

Edge Banding and Finishing

- Purpose: This equipment assists edge banding by keeping parts secure or giving vacuum support for machines that do the process.

- Details: Vacuum systems are good for use with automated edge banding machines. They help hold panels in place when applying the edge material and also remove extra glue or dirt so that the final result is neat.

- Benefits: Improved finish quality, reduced manual handling, and faster processing times.

Cooling and Drying Operations

- Purpose: Accelerate the cooling or drying of adhesives, finishes, or coatings.

- Details: Vacuum systems are beneficial in quickening the drying process of water-based adhesives, coatings, or paints as they help draw air across and through materials. This technique is very helpful for high-production businesses because it helps decrease cycle time significantly.

- Benefits: Reduced drying times, increased production throughput, and improved adhesion quality.

Waste Removal and Recycling

- Purpose: Automatically remove off-cuts, chips, and other waste materials from production processes.

- Details: Vacuum systems that are integrated can effectively eliminate waste materials like sawdust, shavings, and chips by sucking them into collection bins or recycling units. This keeps the production line tidy and productive.

- Benefits: Reduced downtime for cleaning, increased operational efficiency, and better waste management.

Inspection and Testing

- Purpose: Hold parts securely for inspection or non-destructive testing (NDT).

- Details: Vacuum fixtures can keep parts still during quality control inspections. This lets workers examine and test products without using their hands, which is useful in checking things such as surface flatness, joint strength, or material width.

- Benefits: Enhanced accuracy in inspection processes, reduced handling damage, and improved quality control.

Forming and Molding

- Purpose: Aid in thermoforming or vacuum forming for custom mold creation.

- Details: In specific solid surface fabrication operations, vacuum forming methods are used to give shape to acrylic or composite materials over molds and apply even pressure for accurate forms.

- Advantages: The production of forms and molds that are custom-made with high quality, less waste in materials, and accurate management of shaping processes.

CNC Tool Cooling and Chip Evacuation

- Purpose: Assist in cooling cutting tools and removing chips during machining operations.

- Details: Vacuum systems are used with CNC machines for taking out chips and debris made when cutting or milling. This stops any re-cutting from happening and helps the tool last longer.

- Benefits: Improved tool longevity, enhanced surface finish quality, and reduced risk of tool breakage.

Glazing and Panel Assembly

- Purpose: Secure glass or panel components during assembly.

- Details: A vacuum suction keeps the parts steady when glazing or assembling panels, allowing accurate assembly without clamps that could interrupt the process.

- Benefits: Streamlined assembly processes, improved product alignment, and reduced risk of component damage.

Choosing the Right Vacuum Pump for Your Needs

Several types of vacuum pumps are relevant to woodworking and solid surface fabrication, including the following:

- Rotary Vane Vacuum Pumps: Highly versatile, suitable for holding down larger, heavier workpieces.

- Regenerative Blowers: This pump is best used in situations that necessitate a large volume of air movement rather than strong vacuum forces, such as holding porous materials steady.

- Claw Vacuum Pumps: These pumps are gaining popularity for their oil-free operation, energy efficiency, and low noise levels.

- Liquid Ring Vacuum Pumps: Best for environments where moisture or particulates are present. These pumps handle fluids and are suitable for wet materials or coolants.

Selecting the Right Vacuum Pump Involves Considering the Following

- Vacuum Level Requirements: Dense, non-porous materials need higher vacuum levels.

- Airflow Needs: Porous materials benefit from higher airflow.

- Material Properties: Tailor the vacuum pump selection to the material being processed.

- Noise and Maintenance: Choose pumps that fit your noise tolerance and maintenance capabilities.

- Energy Efficiency: Claw pumps are typically more energy-efficient, reducing long-term operating costs.

Diversified Equipment is one of the leading CNC machine distributors, and we supply a range of

CNC wood router machines.

Contact

Diversified Equipment and Supply about how different vacuum pumps for woodworking and solid surface fabrication can enhance your business's performance and profits.

Get In Touch

Thank you for contacting Diversified Equipment. A member of our team will follow up with you within 2 business days. If your needs are more urgent, please call us M-F 8-5 at 704-545-5198.

Please try again later.

© Copyright 2024 | All Rights Reserved | Diversified Equipment and Supply | Powered by WSI-Summit | Privacy Policy| Terms