CNC Optimization Tips: Maximize Efficiency and Performance

Your CNC machines are the heart of your fabrication business – but are you getting the most out of your equipment? CNC optimization increases your machines’ productivity while safeguarding your programs, reducing wear and tear, and boosting efficiency across the board.

Read on to discover practical tips and strategies for successfully optimizing your

CNC stone machines and CNC wood router tips Following these CNC optimization tips can help you improve your CNC performance while keeping your shop running as efficiently as possible, regardless of whether you’re a seasoned CNC operator or just beginning to explore automation.

Understanding CNC Machining Processes in Production Time

Assessing current CNC machining processes is crucial for improving efficiency in a machine shop. By analyzing cutting time and lead time, operators can enhance machining efficiency and precision. Implementing custom CNC solutions, such as standardizing tool setups across multiple machines, minimizes changeovers, saving time and enhancing productivity. By selecting the appropriate tools, manufacturers can minimize tool deflection, reducing stress on the tool and preventing premature wear, thereby extending tool life. Accurately selecting the correct tool diameter and thread pitch is essential for achieving precise threading, ensuring compatibility with fasteners and maintaining optimal results.

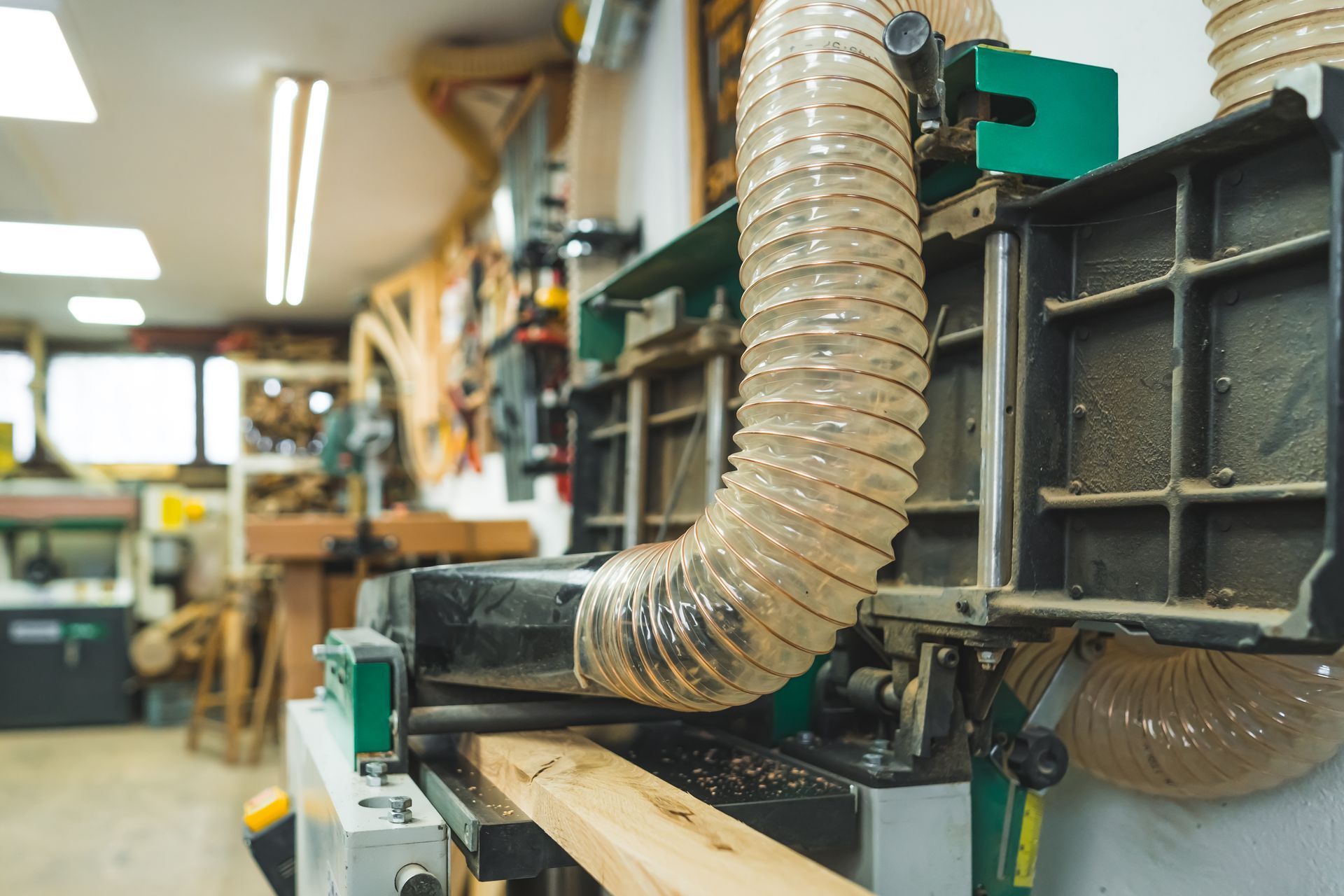

Air-Cooled CNC Spindles for Woodworking Precision and Protection

CNC woodworking routers are designed to operate without liquid coolants, instead relying on air-cooled CNC spindles. This air-cooling approach protects wood materials from moisture exposure, preventing issues like warping or swelling that can occur with water cooling. Since woodworking generates less frictional heat compared to metals or stone, air-cooled systems are more than adequate to maintain optimal temperatures during operation. Air cooling preserves the integrity of the wood and ensures precision during cutting, making it a practical and effective solution for woodworking.

Here are some benefits of air cooling in CNC woodworking setups:

- Prevents Wood Warping: Wood is sensitive to moisture, which can cause swelling or warping. Air cooling eliminates this risk, keeping the wood stable and ensuring precision cuts.

- Reduces Downtime: Air-cooled spindles are generally simpler to maintain compared to liquid-cooling systems, with fewer components that are susceptible to leaks or clogs. This results in minimal service requirements and keeps the CNC wood router running efficiently.

- Energy Efficiency: Air-cooled systems often consume less energy compared to liquid CNC coolants, as they eliminate the need for pumps and coolant maintenance, which helps reduce operational costs over time.

Water-cooled CNC Spindles for Efficient Stone Cutting

Unlike woodworking routers, stone fabrication machines utilize a water-cooled CNC spindle. This cooling method is essential for cutting hard materials like granite, marble, and other stones, as water's high thermal conductivity effectively prevents tool overheating and removes abrasive debris. Water cooling enhances tool longevity by preventing thermal shock and reducing wear, while also maintaining a smooth, dust-free work environment, which is crucial for producing a high-quality finish on stone surfaces. By continuously flushing out dust and debris, water cooling ensures precise, clean cuts, making it an ideal choice for CNC stone applications where polished finishes are required.

Here are a few reasons why water cooling is essential for CNC stone fabrication:

- Reduces Tool Wear: Water helps prevent overheating, extending the life of cutting tools and keeping them sharp.

- Improves Surface Finish: Proper water flow clears away debris, dust, and chips, leaving a clean surface on materials like granite and marble.

- Prevents Material Deformation: Excessive heat can lead to slight deformation in stone, potentially affecting the final product. Water cooling mitigates this risk, improving accuracy in your CNC programming.

How to Reduce CNC Parameters to Maximize Effiency

Carefully evaluating and potentially reducing some of your CNC parameters is one major strategy for enhancing CNC cycle times and protecting your equipment. CNC parameters include things like spindle speeds, feed rates, and depths of cut. While it may seem tempting to push your CNC stone machines or wood routers to their maximum speed, doing this won’t always result in a faster or more efficient job.

Why reducing CNC parameters works:

- Prevent Machine Overload: Moderate speeds give you a smoother, safer operation. Running machines at their maximum spindle speed might lead to overheating, increased wear, and, eventually, machine downtimes for repairs or adjustments.

- Better Surface Quality: Reducing feed rates allows for more precise cuts and a finer finish. Pushing your machines too hard can compromise surface quality, resulting in rough edges or a loss of detail in both wood and stone projects.

- Improved Tool Longevity: High parameters often lead to quicker tool degradation. Slowing down just a bit will extend tool life and reduce your operational costs.

Smooth Filters to Improve CNC Performance

An often overlooked aspect of CNC optimization? The implementation of smooth filters to reduce vibrations and improve machine motion. You can add these advanced filtering algorithms to a program for CNC machine operations to produce smoother movement paths, leading to increased precision and greater longevity for the machine.

Advantages of smooth filters in CNC machines:

- Enhanced Accuracy: Smooth filters reduce overshooting or jerky movements that can affect intricate designs.

- Vibration Reduction: CNC stone machines and wood routers are prone to slight machine vibrations when moving rapidly between positions. These vibrations can cause inconsistent cuts and reduce part quality. Smooth filters help to eliminate this, providing steadier movement.

- Decreased Maintenance and Wear: When machine movements are more controlled, there’s less strain on the machine’s moving parts, particularly in the CNC drive systems. This means fewer mechanical issues and less frequent maintenance.

Minimizing Tool Changes to Improve CNC Cycle Times

Tool changes are a necessity when dealing with various cutting techniques and materials, but frequent tool swaps can drastically increase CNC cycle times and slow down production. While you can’t eliminate tool changes entirely, there are strategies to minimize them. Here’s how:

- Smart Tool Path Programming: Always set up the tool paths to minimize tool changes when creating a program for CNC machine jobs. Group similar operations together so tools stay in longer.

- Invest in Multi-Tool Spindles: Some advanced CNC wood router machines and stone-cutting tools are equipped with multi-tool systems that allow for quicker tool changes without stopping the production cycle.

- Use Multi-Function Tools: In some cases, multi-function tools can serve several cutting purposes without requiring a change. From materials like quartz and granite to engineered wood, using versatile tooling whenever possible keeps your cuts consistent and minimizes the need for swapping tools.

Want to explore more ways to upgrade your CNC performance?

Contact Diversified Equipment and Supply. As one of the top

CNC machine distributors in North Carolina, we provide the right solutions to keep your CNC stone machines and CNC wood router machines running at peak performance with our CNC optimization tips.

Get In Touch

Thank you for contacting Diversified Equipment. A member of our team will follow up with you within 2 business days. If your needs are more urgent, please call us M-F 8-5 at 704-545-5198.

Please try again later.

© Copyright 2024 | All Rights Reserved | Diversified Equipment and Supply | Powered by WSI-Summit | Privacy Policy| Terms