Boosting Productivity with a CNC Machine Maintenance Guide

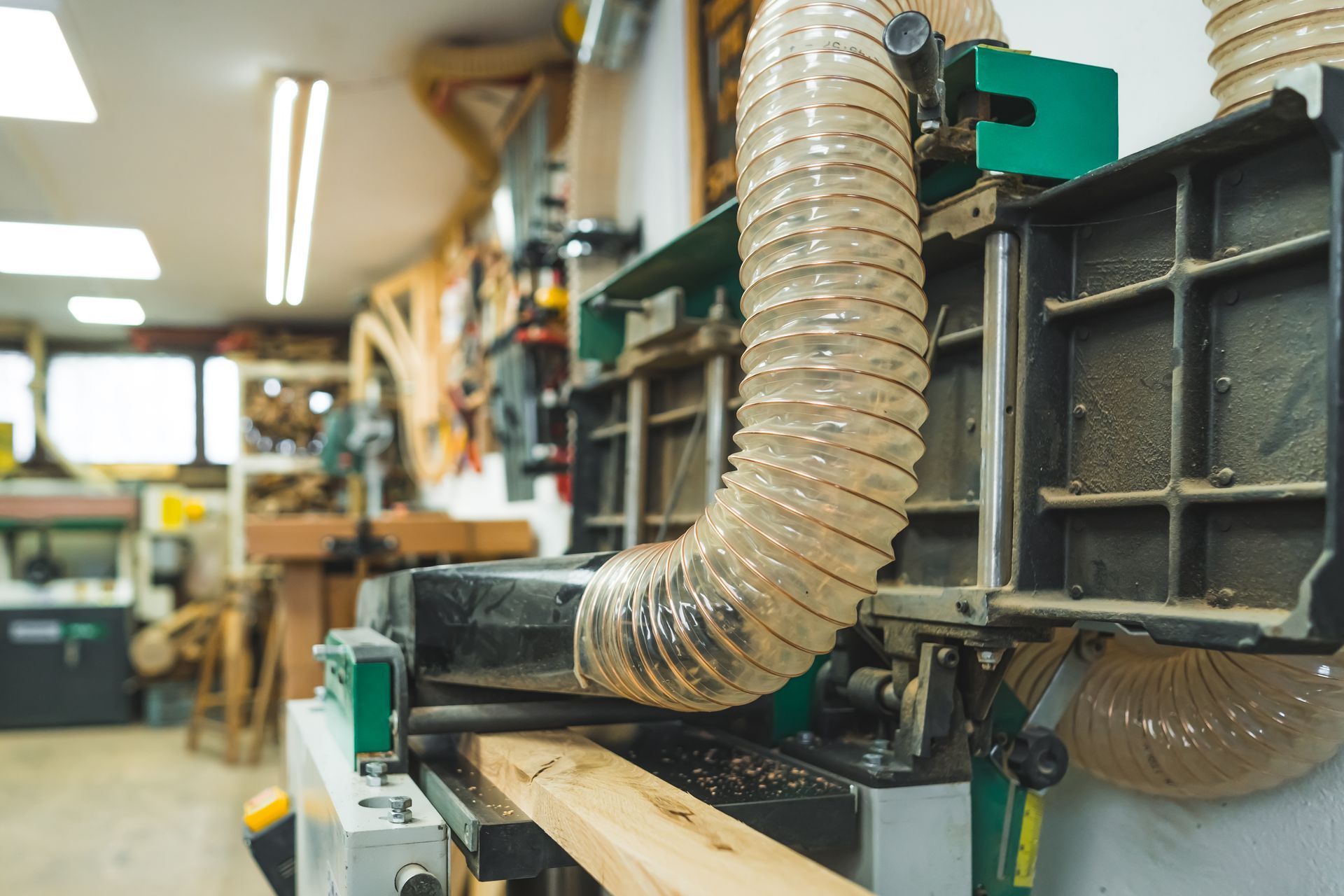

CNC machine maintenance is essential because these machines have completely transformed how businesses approach stone fabrication. These essential tools promise precision, efficiency, and profitability – however, like any piece of advanced machinery, CNC equipment requires regular maintenance to function at its best and stand the test of time. Ensuring consistent quality and maximizing the lifespan of your investment to avoid unexpected downtime is a must, and it involves incorporating a solid maintenance plan. But where to begin?

This pocket guide will walk you through key maintenance aspects of

new and used CNC machines, including CNC electrical maintenance, CNC drive systems, CNC machine spindle, and CNC vacuum hold-down system maintenance. Follow these best practices to keep your shop in tip-top shape.

Common CNC Maintenance Challenges

Effective maintenance of CNC machines is crucial for ensuring precise operations and minimal downtime. These are the most common challenges with CNC maintenance:

- Poor Maintenance

- Overheating

- Mechanical Issues

- Electrical Problems

- Software Errors

- Vibration and Chatter

- Dust Accumulation

- Time Constraints

CNC Machine Maintenance Checklists

A comprehensive maintenance checklist is essential for preventing downtime and costly repairs

Daily Maintenance

Daily tasks include cleaning the machine bed and slide rails, checking indicator lights, testing emergency push buttons, inspecting hydraulic systems, and verifying coolant levels

Weekly and Monthly Maintenance

Weekly and monthly checks involve tasks like spindle inspections, axis lubrication, and coolant system maintenance. Every 500 to 1,000 hours, tasks such as greasing chip conveyors, inspecting chucks, and replacing fluids are necessary

Yearly Maintenance

Annually, more thorough inspections are required, including cleaning coolant tanks, replacing lubricants, and checking for software updates.

CNC Electrical Maintenance

Electrical maintenance is the foundation of your CNC machine’s reliability and longevity. The intricate network of wires, sensors, control systems, and motors all depend on clean and stable electrical connections.

Here are some tips for approaching CNC electrical maintenance successfully:

- Inspect Wiring and Connections Regularly: Factory vibrations can loosen electrical connections over time, resulting in your machines malfunctioning. It’s best to check all wiring and connectors monthly to ensure they’re secure.

- Clean Electrical Cabinets: Keep cabinets sealed, dust-free, and dry to avoid overheating or short-circuiting.

- Monitor Power Supply: Test voltage levels regularly to ensure your machine is receiving consistent power. Fluctuations in voltage can harm vital CNC components such as the CNC drive systems and spindle motors.

- Check Fuses and Breakers: Damaged fuses or breakers can cause your CNC to stop suddenly or experience intermittent issues – always keep replacements on hand.

CNC Drive Systems Maintenance

CNC drive systems provide the precision and speed needed for accurate cutting and shaping. Here’s how to stop these systems from wearing out, helping you avoid frequent breakdowns and reduced product quality.

- Lubrication: Ensure all moving parts involved with the CNC drive system are well-lubricated using the right type and the right amount of lubrication fluid – refer to the manufacturers’ instructions.

- Belt and Chain Tightness: Check that belts and chains within the drive system maintain the correct tension. Loose belts or chains can result in misalignment and inconsistent product finish.

- Cleaning: For streamlined functioning, keep the drive systems clean, particularly in environments where fine stone dust is prevalent.

CNC Machine Spindle and Tool Holder Maintenance

The CNC machine spindle and tool holders play the lead role in the cutting process, delivering precision and power. Here are some tips for keeping them in excellent condition:

- Spindle Warming Up: Always allow your CNC spindle to reach its operational temperature at the start of the day, especially after long downtimes. This will ensure the spindle doesn’t experience thermal shock, which can result in premature wear.

- Inspect for Wear: Routinely check the tool holder and spindle for cracks, dents, or signs of wear.

- Clean Tool Holders: Residue from previous jobs can accumulate on tool holders, leading to poor grip and imprecise cuts – keep them clean.

- Prevent Spindle Overheating: A faulty cooling system can cause your CNC machine spindle to overheat, leading to costly spindle rebuilds or replacements. Make sure the cooling system, if present, is functioning properly, and regularly check spindle temperature sensors.

CNC Vacuum Hold-Down System Maintenance

The CNC vacuum hold-down system keeps material secure during cutting for precision and to reduce waste. These are some steps for maintaining your CNC vacuum hold-down system:

- Check for Vacuum Leaks: Periodically test for leaks in seals, hoses, and vacuum beds to maintain hold-down strength.

- Clean the Vacuum Table: Don’t allow dust, debris, or residue to clog the holes in the CNC vacuum hold-down system, diminishing its effectiveness. Clean the vacuum table and pipes for strong negative pressure.

- Maintain Vacuum Pumps: Vacuum pumps are responsible for creating the suction that holds your materials down. Check and maintain the pumps according to manufacturer instructions, ensuring all filters are clean and the oil levels are adequate.

- Inspect Gaskets and Seals: The gaskets and seals in your CNC vacuum hold-down system can wear down, especially when cutting abrasive materials like granite and quartz. Keep a close eye on these components and replace them as necessary.

How Often Should CNC Machine Maintenance Be Done?

Establishing an effective maintenance program for your CNC machines is essential to ensuring optimal machine performance. Regular daily maintenance tasks should focus on checking machine conditions and ensuring the coolant and hydraulic systems are functioning properly. A seasoned maintenance team can implement a preventive maintenance system that includes machine inspection and scheduled maintenance to reduce downtime and extend the lifespan of your CNC equipment.

Developing an annual maintenance plan with defined maintenance intervals helps track machine usage and anticipate machine breakdown. Utilizing a computerized maintenance management system allows businesses to make informed business decisions regarding spare parts and necessary maintenance work. Ultimately, machine replacement is dictated by the effectiveness of the internal maintenance practices which Diversified Equipment and Supply assists with

Schedule CNC Maintenance with Diversified Equipment and Supply

CNC machines, including CNC wood router machines, are a significant investment—a machine that can quickly pay for itself by increasing productivity and minimizing manual labor with consistent, high-quality results. Contact Diversified Equipment and Supply – your trusted CNC machine distributors in North Carolina – to discuss CNC machine maintenance and how our CNC stone machines can help your business grow and maintain profitable, efficient operation year-round.

Get In Touch

Thank you for contacting Diversified Equipment. A member of our team will follow up with you within 2 business days. If your needs are more urgent, please call us M-F 8-5 at 704-545-5198.

Please try again later.

© Copyright 2024 | All Rights Reserved | Diversified Equipment and Supply | Powered by WSI-Summit | Privacy Policy| Terms