Are CNC Stone Machines Right For Your Business?

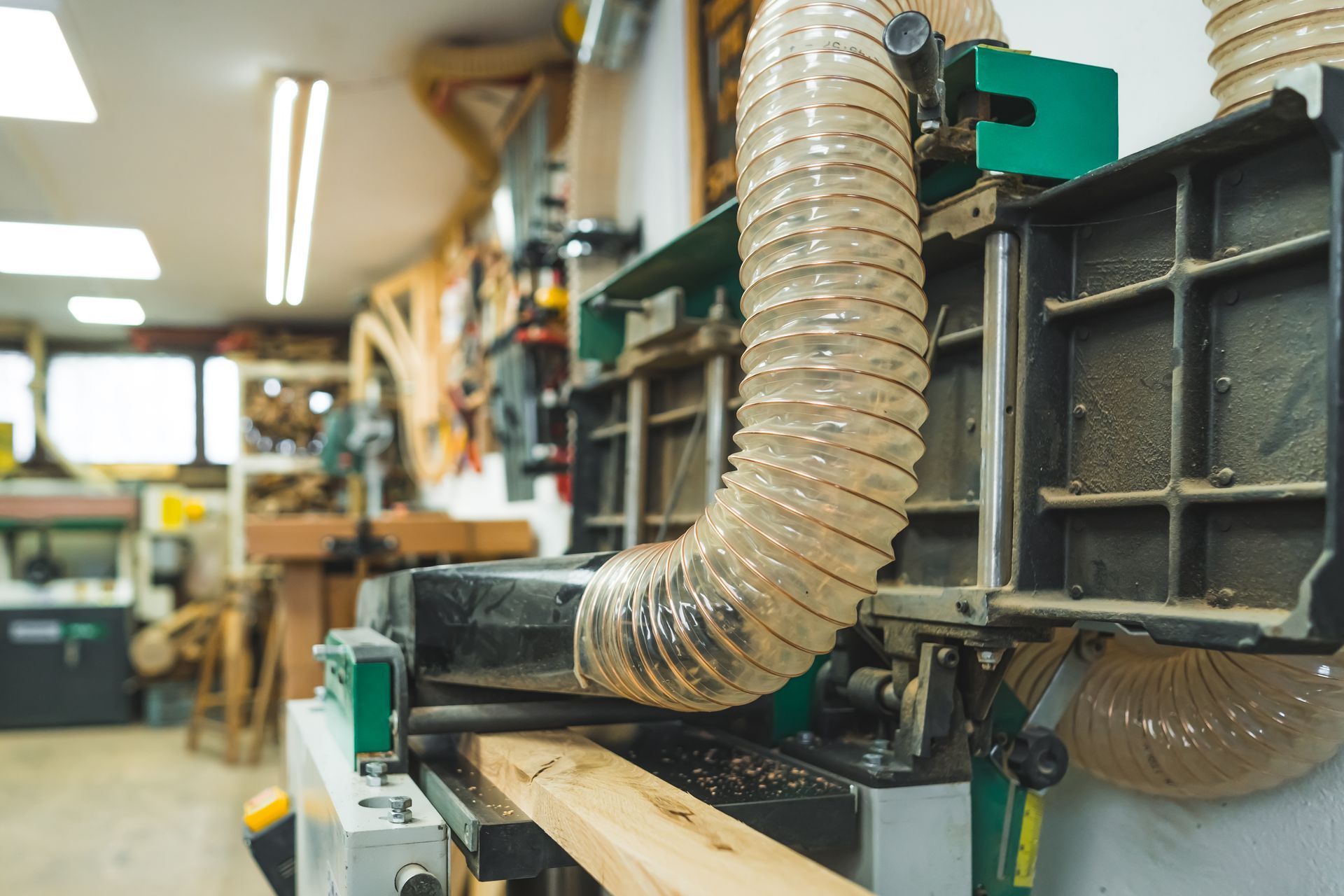

From routers to bridge saws and more, how to know if your stone fabrication business can benefit from automated equipment.

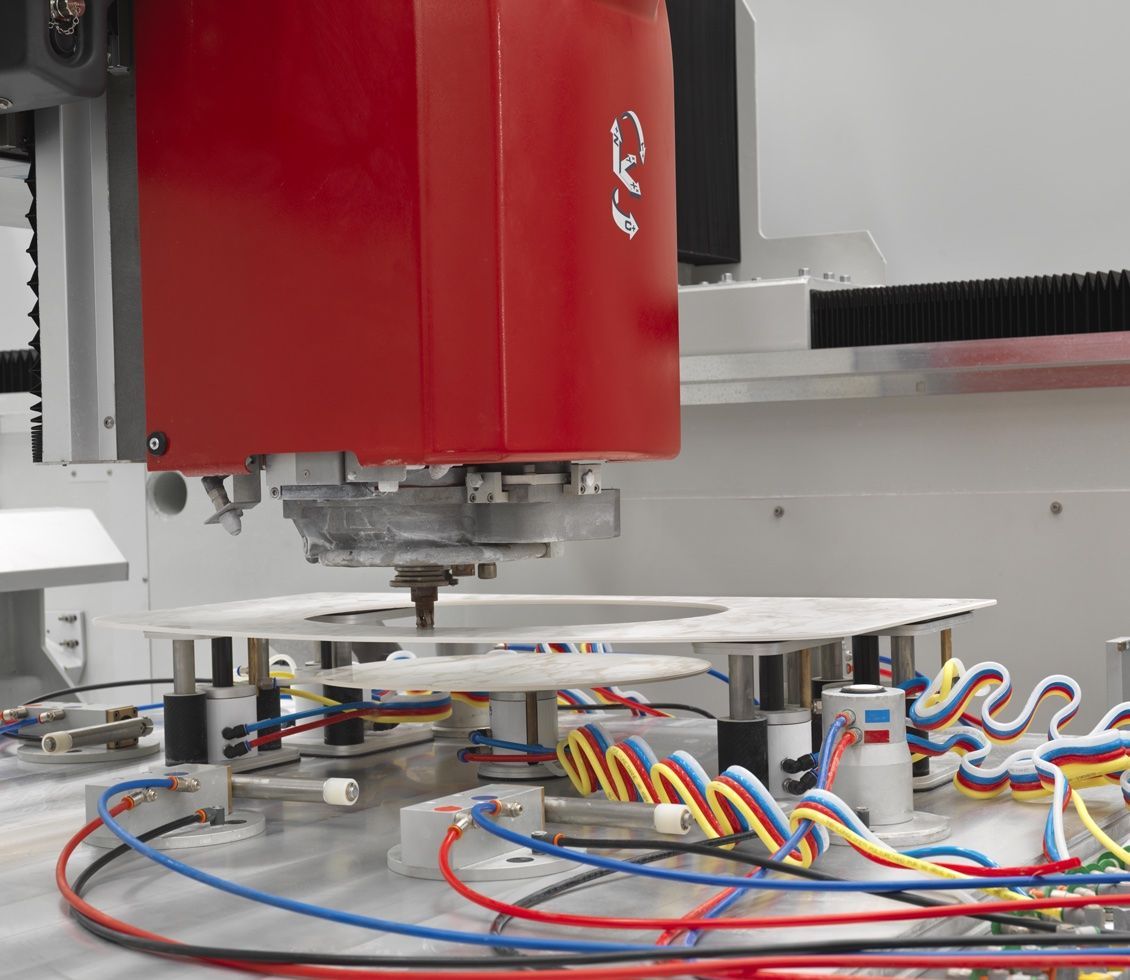

Businesses continuously seek ways to boost efficiency, enhance quality, and maximize profitability in today's competitive manufacturing sector. Using CNC stone routers and saws is one way to do this.

The numerous advantages that stone CNC machines have over conventional manual methods make them a desirable alternative for companies being challenged by having to train skilled labor. Automated technology offers extraordinary precision and accuracy ensuring consistent high-quality finishes with reduced man hours.

Wait, so you’re thinking no way this will help our company, we never do the same thing twice, our work is ALL CUSTOM….. Right? Well, not really, in fact, almost none of our customers do the same thing twice. Yes, there was a day when that statement made sense, but those days are long gone.

These machines can easily carry out precise one time cuts and complex miters because of the accuracy and solidity of the computer-controlled automation, which removes the constraints of physical labor. This level of accuracy promotes more effectiveness, less waste, and faster production cycles, ultimately increasing overall output. And often times produces a much more predictable labor cost.

Ask yourself about that week you barely completed any jobs but you still had a full 40 hour week, or worse yet, had overtime and compare that labor to the week you shipped a record number of jobs. Consistency will win the race, inconsistency will reduce your bottom line profit.

Are you able to afford a CNC Stone Router and Saw?

While there is no denying the advantages of CNC stone machines, many companies are still determining if they can afford this cutting-edge equipment. When assessing the cost-effectiveness of CNC machines, it's crucial to consider the long-term advantages and return on investment.

Diversified Equipment & Supply (DES) understands how businesses need to balance their budgets. We offer a variety of solutions as a supplier of manufacturing equipment to accommodate various budgets and specifications. Our team can assist you in locating a CNC stone machine that complements your financial resources and production requirements, whether you run a small business or a larger organization.

Additionally, DES offers support services and financing solutions to help firms buy CNC stone equipment. We are dedicated to assisting you in expanding your business more profitably because making the appropriate equipment investments can positively influence your bottom line.

What should I consider before buying a CNC machine?

You should think about several things to make sure the CNC router or saw you buy is the best fit for your company.

First and foremost, evaluate your unique production needs. The labor you have currently going into every top and the reliability in hard-to-find employees that is taking a toll on your business. Finding an employee that will show up every day and do exactly what you asked them to do is the key. Find that person in the shop who takes charge as a leader, pride in their work, and is always looking for a better way to get the job done. That’s very likely your new CNC operator should you choose to empower both that individual and your business in taking the step forward.

Buying a CNC is less than half the equation, you must adopt new ways of thinking because it will change how you do things and how fast you can get it done too. Plan to keep your crew busy because they are going to have less labor to add to the work. Nevertheless, it is quite common to experience a surge in workload when you decide to take on projects that come with a certain level of uncertainty regarding their profitability. You see with the automation you will find that predictability will increase your capacity and ability to compete in the market.

Selecting a machinery supplier goes beyond simply being drawn to the paint scheme, following a friend's recommendation, or the country of origin. The most crucial factor to consider is the supplier's viability. Buyers are often swayed by emotion, just as with any significant decision.

Ask yourself these questions:

- How long has the supplier been building machines and how many are in the field not just locally, but globally?

- Is the salesperson asking you questions about how the machine will integrate into your operations? Make sure they understand your current process and how it can be implemented. Many customers are afraid to say I don’t know, please explain. The time to ask is before you buy, because picking the wring partner may be expensive later.

- Is your provider asking questions about other flow processes that will be affected by the automation?

- How long can you reliably get parts for the machine?

- Understand that a partner for your business is there to advocate for you when you are having problems and to make sure you are getting what was promised and we don’t forget that part. Having a liaison who is on your team means looking at your business from the inside out to help you save wasted time and effort costing you money.

- The reputation and experience of the equipment vendor should also be taken into account. In addition to providing complete support, does the vendor also provide operator training, equipment installation, and ongoing support throughout your investment?

About Diversified Equipment and Supply

A reputable supplier of manufacturing equipment, DES is committed to assisting companies in raising productivity, enhancing quality, and maximizing profitability. With more than 40 years of expertise, we have established ourselves as an industry "Production Partner" and "Trusted Advisor".

From one-person operations to corporations with more than 200 employees, our integrated CNC systems serve businesses of all sizes. With our complete solutions, you get everything from setting up the hardware to developing the software to providing ongoing support. To ensure that the equipment you invest in aligns with your goals and yields the desired outcomes, our team of experts focuses on understanding the dynamics of your business and its financial position.

At DES, we do more than sell equipment; we become an essential business resource, assisting you as you expand and change. Our shop layout services, equipment maintenance programs, repairs, and training programs are created to support you in streamlining your operations, increasing productivity, and achieving long-term success.

Get in touch with DES to learn more about our selection of CNC stone machines and how we can support your company's success. Let us partner with you to drive productivity, quality, and profitability.