Woodworkers' CNC Wood Router Buying Guide

In this wood router buying guide, we discuss the considerations for choosing a wood router. All the way back in 1884, American pattern maker Henry Cope designed a wood machine to cut flat-bottomed, rounded, or V-shaped grooves. This limited use invention was arguably the first wood router machine.

We have come a long way since then! The most recent development in wood routers - CNC wood routers - began appearing in the 1970s and have become an essential tool for many woodworkers and manufacturers. What to consider when you want to buy a wood CNC machine:

Types of CNC

There are several types of industrial wood router machines that are available on the market, each with their own specific features and capabilities.

CNC Wood Router

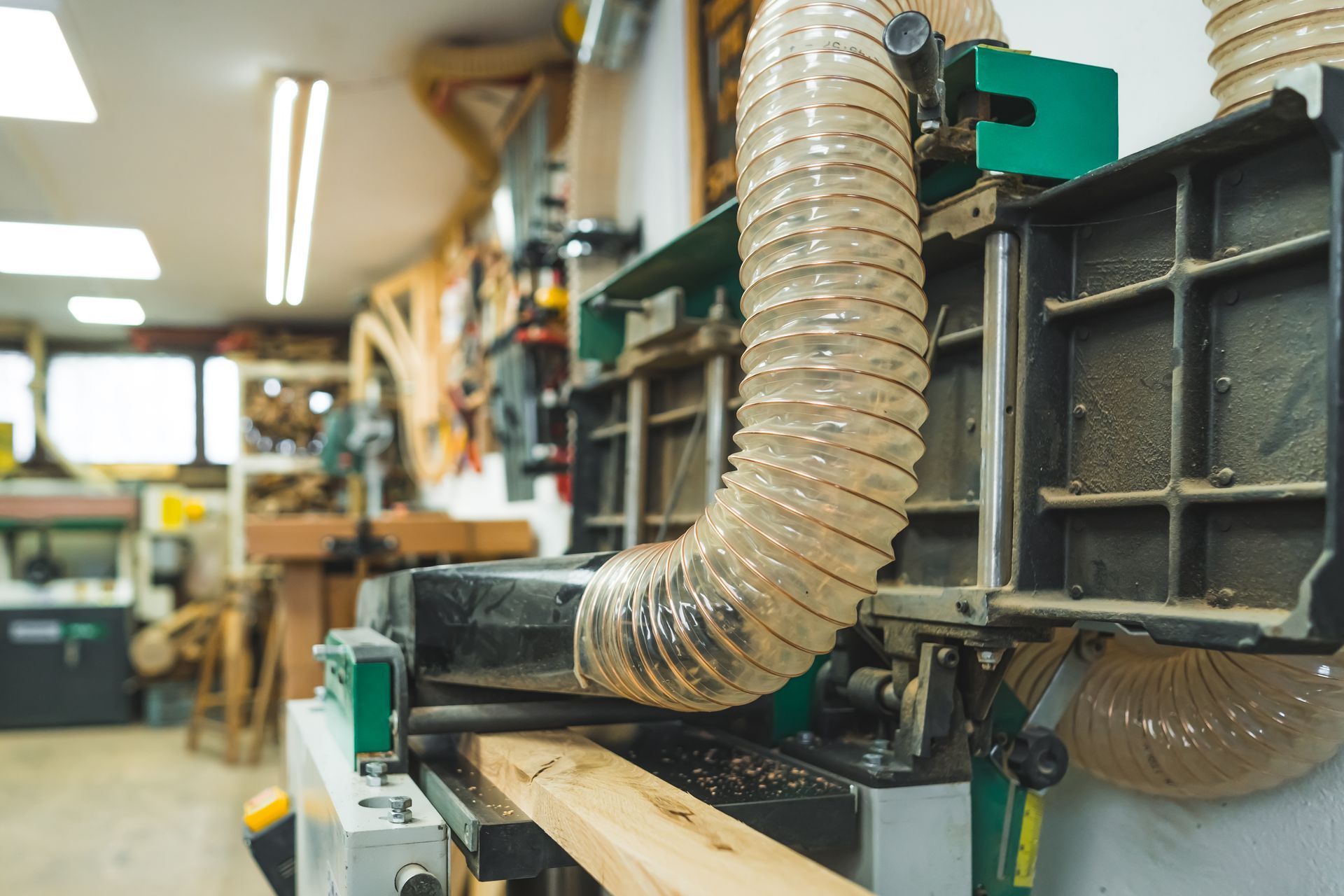

A CNC wood router is a versatile machine used for cutting, carving, and engraving wood materials. It operates using computer numerical control (CNC), ensuring precise and repeatable results. These machines are ideal for intricate designs, custom cabinetry, and furniture production. They can handle tasks such as engraving logos, carving 3D shapes, and cutting multiple wood sheets at once with exceptional accuracy. CNC wood routers are equipped with features like automatic tool changers, dust collection systems, and compatibility with CAD/CAM software, making them a staple in modern woodworking shops.

CNC Wood Milling Machine

CNC wood milling machines are specialized for tasks requiring high precision in shaping and cutting wood. Unlike standard routers, milling machines can cut complex geometries and contour surfaces with a higher level of depth and detail. They are typically used for producing parts such as wooden molds, furniture components, and prototypes. With advanced spindle speed control and multiple-axis movement, these machines are perfect for intricate designs and high-volume production. CNC wood milling machines also excel in material removal, creating smooth finishes and reducing the need for post-processing.

CNC Wood Lathe

A CNC wood lathe is designed for crafting cylindrical or symmetrical objects like table legs, stair spindles, and decorative columns. This machine rotates the wood stock while cutting tools shape it to the desired design, all controlled by pre-programmed CNC software. CNC wood lathes can handle both simple and complex designs, providing excellent consistency and accuracy in mass production. Features like automatic tool adjustment and multi-axis movement enhance efficiency, allowing users to complete complex turning projects with minimal operator involvement.

Laser CNC Machine for Wood

Laser CNC machines for wood use high-powered lasers to cut, engrave, or mark wood surfaces with exceptional precision. These machines are ideal for intricate designs, delicate engravings, and creating detailed patterns. Laser CNC machines can handle various wood types, including plywood, MDF, and hardwood, without physical contact, reducing the risk of material damage. They are commonly used in industries requiring fine detailing, such as custom signage, decorative panels, and personalized products. Advanced models offer features like variable power settings and adjustable cutting depths for maximum versatility.

Key Features of CNC Wood Machine Routers

CNC wood routers offer a wide range of features to help users create precise and complex cuts and patterns:

- Computer control. CNC routers often come with software that allows the user to create and edit cutting programs, as well as to control the machine's movements.

- Multiple axes, including the standard X, Y, and Z axes, as well as additional rotary axes for cutting at various angles.

- High precision, with accuracy often measured in thousandths of an inch.

- High speed, making them well-suited for production work.

- Large working area suitable for cutting large and small pieces of wood or for cutting multiple parts at once.

- Variety of cutting tool heads - including end mills, drills, and saw blades - to achieve different cuts.

- Dust collection system to help keep the work area clean and reduce the amount of dust in the air.

- Safety features such as emergency stop buttons, interlock switches, and enclosures to protect the operator.

- Some CNC routers can be integrated with other machines, or with different software to expand their capabilities.

How to Find the Best CNC Wood Router

When buying CNC wood routers for woodworking, ask yourself the following questions:

- What size and type of wood, panel or product will the machine be required to handle? Not only for today but in the future.

- How accurate and fast do you need the router to be?

- What level of automation do you require?

- Cut Only, Automatic offload, Automatic Load, Automatic Material Delivery

- How easy is it to operate the machine's control system?

- Does the machine come with any technical support and/or training.

- Is it compatible with any existing software or equipment you are already using?

- What is the overall build quality and durability of the machine?

- How heavy, how well built, how long do you want it to last

- Compare the specifications of different models, including cutting area, spindle power, and accuracy.

When you are clear about these criteria, it will be a lot easier to source an appropriate CNC wood machine router.

About Diversified Equipment and Supply CNC Routers

We get our name from the diversified tools we supply and the industries we serve. Our team has over 100 years of combined experience in multiple industries. The common thread that unites our clients is the desire to provide the best solution to maximize your business’s profitability.

Whether you are looking for a new or used machine, trust our 40 years of experience to provide the most suitable CNC wood machines for your needs.

Get in touch with

Diversified Equipment for more information if this wood router buying guide helped you consider buying

CNC equipment.

Get In Touch

Thank you for contacting Diversified Equipment. A member of our team will follow up with you within 2 business days. If your needs are more urgent, please call us M-F 8-5 at 704-545-5198.

Please try again later.

© Copyright 2024 | All Rights Reserved | Diversified Equipment and Supply | Powered by WSI-Summit | Privacy Policy| Terms