Wood Router Safety Tips for Safe Industrial CNC Operations

Wood Router Safety Tips for Safe Industrial CNC Operations

The proper handling and operation of wood routers are essential for both output and safety. Good wood router safety practices, complete with PPE, safety precautions and strict operation procedures, will help to optimize your work and keep you safe. Here are some tips you can use on your shop floor.

Essential Woodwork Safety Equipment

Personal protection equipment is essential for wood router operators. It can be tempting to skip some of this equipment and just trust that everything will go well, but why take that risk? Wood router PPE is comfortable enough to wear and will ensure that your hands, eyes, ears and feet are kept safe as you do your work. You will need:

- Safety Goggles to protect your eyes against dust and other debris.

- Ear Muffs: Loud machinery can damage your hearing, so wear these to protect your ears from prolonged exposure to machine noise.

- Dust Mask: The inhalation of dust particles can be hazardous to your health. Wear a mask to filter out the dust.

- Non-Slip Footwear: Avoid slips and falls that can lead to serious injury, by wearing non-slip boots or shoes.

- Appropriate Clothing: Be careful not to wear loose-fitting clothes or accessories that could get caught in the machine.

- Operational personnel should always be fully trained in the use of PPE as well as other safety precautions.

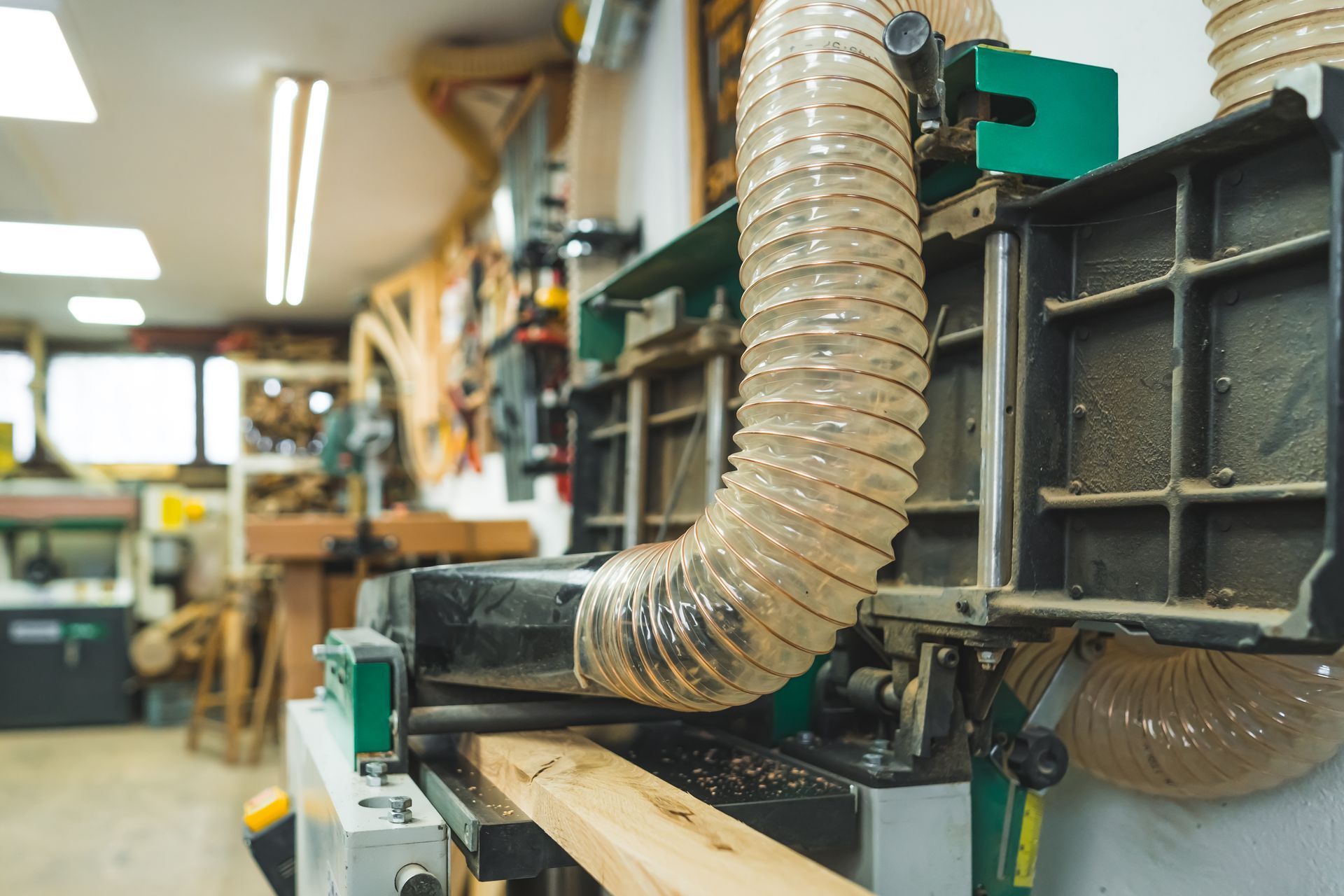

Wood Router Maintenance for Optimal Performance

Proper maintenance prevents costly breakdowns on your wood router, and also reduces the likelihood of injuries. These tips will help you keep your router in excellent shape:

Thoroughly clean both the machine and the surrounding area. No dust or debris should be allowed to settle into the router's working parts.

- Inspect components such as belts, screws, and bearings for wear and tear.

- Lubricate all moving parts using a manufacturer-approved lubricant.

- Ensure that all worn out parts are replaced without delay.

- Diversified Equipment offers maintenance plans for your CNC routers.

Steps for Ensuring Wood Router Safety

Make the following safety precautions an important part of preparation:

- Pre-Operation Checks: Make sure that all moving parts are securely placed. If the machine is not plugged in, check that the switch is in the off position before connecting it.

- All machine operators must be fully trained in how to use the machine before they are allowed to operate it.

- Maintain a working culture and area that is free of distraction A professional, mature attitude is essential to ensure that operators can focus all their attention on the work at hand.

- Always use the correct bit for the task at hand. Check that the bit is properly and securely fitted.

- Watch your body positioning: Keep your hands and other body parts at least six inches away from the bit and other moving parts.

- Secure your workpieces carefully: Make sure all workpieces are firmly clamped down.

- Put emergency procedures in place and make sure everyone is familiar with them.

How to Use a Wood Router Correctly

It may seem an obvious point, but one of the best ways to stay safe when operating a wood router is to make sure you are using it correctly:

- Start with the correct tool setup: Choose the right bit and install it securely.

- Adjust the router speed to suit the material you are working on - higher for softer workpieces, lower for harder materials.

- Maintain a consistent feed rate so the router does not get overloaded.

- Don't cut too deeply on the first pass. Perform a number of passes, gradually increasing the depth.

Follow these safety tips for optimal, accident-free wood router operation. For any questions or further assistance regarding wood router safety, contact Diversified Equipment. Our team of professionals provides complete support, from equipment installation to operator training and maintenance.