CNC Routers: What Does It Do and How Does It Work?

A CNC router: what does it do? It transforms woodworking, automating intricate cutting, carving, and shaping tasks with precision. Unlike manual tools, a CNC router uses computer-guided technology to create detailed patterns and designs across materials like wood, plastic, and soft metals. This post explores what a CNC router is, how it works, its parts, and common applications in woodworking operations.

How Does a CNC Wood Router Work?

A CNC wood router automates complex woodworking tasks by turning digital designs into precise physical creations. Here’s how it works:

- CAD Design: The process begins with Computer-Aided Design (CAD) software, where a user creates a 3D model of the desired object.

- G-Code Translation: The CAD design is converted into G-code by Computer-Aided Manufacturing (CAM) software. This code instructs the CNC router on how to move.

- Precise Execution:

The CNC router spindle, armed with specific cutting tools, moves across the x, y, and z axes to shape the material.

The spindle of the CNC wood router, which has different cutting tools attached to it, then understands this G-code and moves along the x, y, and z axes. This specific movement lets the router shape things out, make holes, and form textures on the material surface. The work done by a wood router is remarkable thanks to its precision and capacity to make parts that are identical in high quality repeatedly. The ability to work with a wide range of materials, including wood, plywood, medium-density urethane, and even harder materials like hardwoods such as oak, makes CNC routing indispensable in the woodworking industry. CNC routers are used to cut and remove material with high precision and are capable of handling complex shapes and geometries.

The components of a CNC router, such as stepper motors, servo motors, a gantry, and an automatic tool changer, ensure productivity and efficiency by reducing human error and allowing for the machine to complete tasks with remarkable accuracy. The tool changer, for instance, can automatically swap out tools, making the machine suitable for CNC milling and capable of performing various tasks without manual intervention.

Whether you're crafting furniture or intricate wood patterns, CNC wood routers deliver unmatched accuracy and repeatability.

Uses for CNC Routers in Woodworking

CNC routers are versatile and essential tools for modern woodworking. Here are some common applications:

- Custom Cabinetry: Craft cabinets with intricate designs and precise dimensions.

- Furniture Making: Create components like table legs, chair frames, and decorative panels.

- Signage: Engrave and carve letters, logos, and designs into wood.

- Architectural Elements: Fabricate complex designs like molding or decorative columns.

These uses demonstrate the significant productivity and creative potential of CNC routers in woodworking.

How to Use a CNC Wood Router

Using a CNC wood router involves several steps to ensure precise results:

- Design Your Project: Begin with CAD software to create a digital blueprint of your design.

- Set Up the Router: Mount your material securely on the CNC router table and attach the appropriate bit for the task.

- Input G-Code: Upload the G-code instructions to the CNC router.

- Run the Machine: Monitor the machine as it executes the design, ensuring proper function and safety.

- Finish and Inspect: Once the job is complete, inspect the results for accuracy and quality.

Learning how to use a CNC wood router effectively can unlock its full potential for your projects.

Common Parts of a CNC Wood Router

The effectiveness of a CNC router is determined by these key components:

- Spindle: Rotates at high speeds to cut through material.

- Stepper Motors and Servo Motors: Provide precise movement across axes.

- Tool Changer: Automatically switches tools for varied tasks.

- Router Bits: Different bits are used for tasks like engraving, shaping, and cutting

What Are the Parts of a Wood Router?

A CNC wood router's versatility is linked to the variety of router bits it can accommodate. Each bit has a certain function and material, making it useful for particular tasks. Here are some types that are commonly used with wood:

- Straight Bits: They are used for creating straight cuts in the material to make grooves or dadoes.

- V-Groove Bits: Ideal for engraving and creating V-shaped channels in the workpiece.

- Ball nose bits: Usually employed for 3D contouring and milling, these make rounded grooves and complex details.

- Flush Trim Bits: They assist in cutting the edges of one material so that they align with the surface of another.

The bit you choose is very important to get the final look and detail in wood router work. CNC routers offer high-speed spindles or routers, which are controlled by CAM software programs. These machines are designed to handle a wide range of materials, from soft materials like medium-density urethane to harder materials like hardwoods such as oak.

Common Wood Router Bits

Efficiency and productivity are crucial factors in maximizing profits. CNC Stone Routers and Bridge Saws excel in both areas by streamlining manufacturing processes and minimizing costs. These machines operate with high precision and speed, completing tasks in a fraction of the time it would take using manual methods.

Automation eliminates the need for extensive manual labor, reducing labor costs and increasing overall productivity. Additionally, CNC stone machines minimize material waste by optimizing the cutting process and maximizing material utilization. This reduction in waste saves costs and leads to significant savings in raw materials. By increasing productivity and reducing manufacturing costs, businesses can experience substantial improvements in their bottom line.

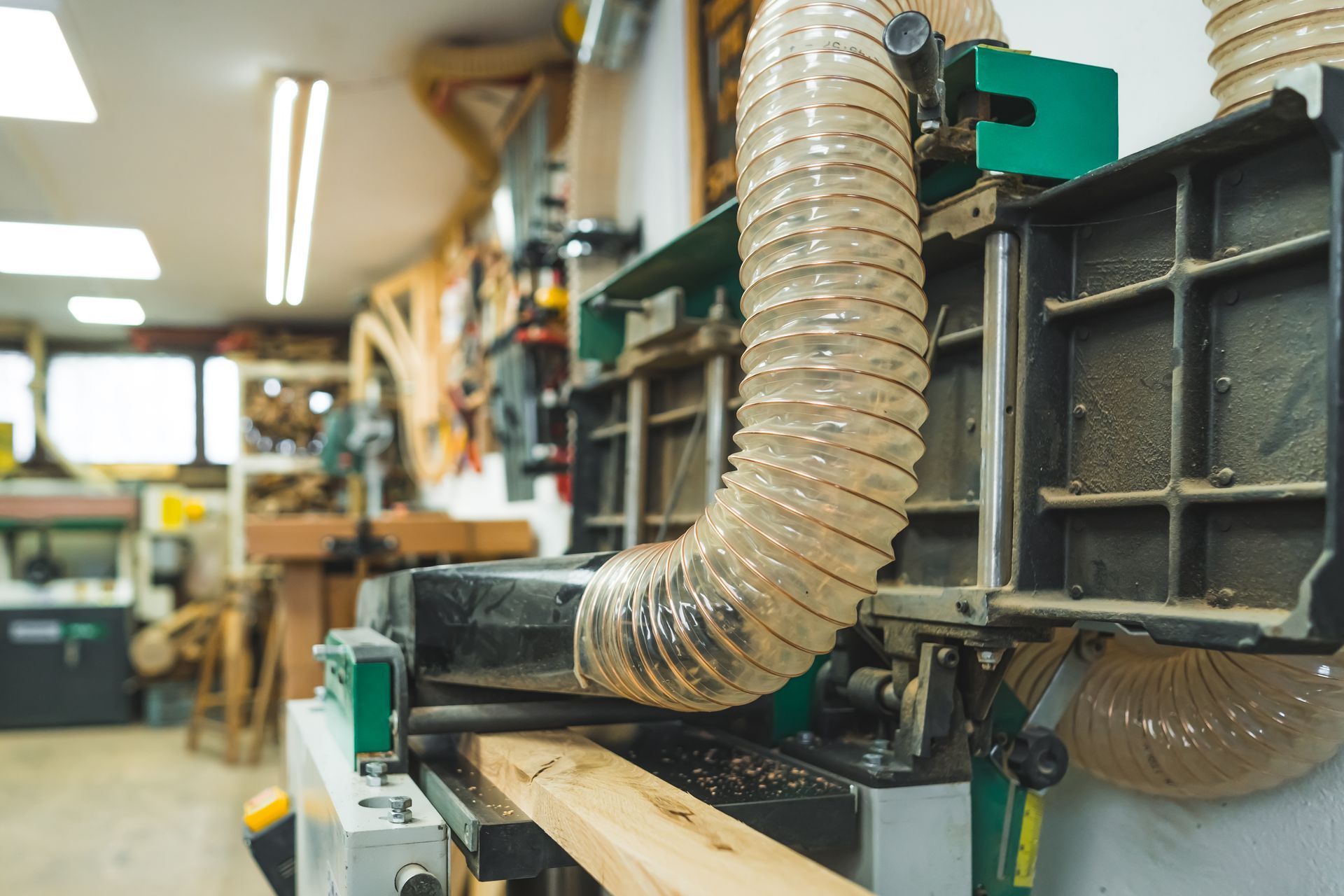

Using A Wood Router Table

A CNC wood router table, a vital part of a woodworking workshop, can boost the functionalities of the CNC router. This table helps in steadying the material for better cuts by providing stability. It also offers more space to work on, making it easier when dealing with larger panels or sheets.

The use of a CNC wood router table guarantees accuracy in each cut and minimizes the possibility of mistakes, making it perfect for detailed designs and repeated production runs. Diversified Equipment, which is skilled at delivering quality CNC solutions, has different types of CNC wood router tables available that are made to match the requirements of both small shops and big industrial operations.

Why Choose Diversified Equipment for CNC Wood Routers?

At Diversified Equipment, we specialize in helping businesses select the perfect CNC solutions to meet their needs. With our expertise, you’ll gain access to:

- Top-Tier Equipment: High-quality CNC routers and supporting tools.

- Personalized Support: Expert advice on selecting and maintaining your CNC router.

- Long-Term Reliability: Equipment that boosts productivity and profitability over

Contact us today and let our experts help guide you toward towards buying your CNC router and see what it does for your project.Trust

Diversified Equipment to provide the tools you need to succeed.