A Look at the Key Features of a CNC Machine for Wood

Understanding CNC wood machines is very important to anyone who wants to boost their woodworking projects. Investing in the right machine can make a big difference in how productive, good-quality, and profitable your work becomes. Here are some of the main features you should consider when picking out a

CNC wood machine:

Consider Your CNC Area Workspace

Before buying a CNC wood router machine, assessing your CNC area workspace is very important. The term "envelope" or cutting area refers to the size of workpieces you can handle with this machine. For example, if you want to make signs from plywood sheets 4 s ft. x 8 ft., a large machine will be necessary for this project. It's important to consider how you will use the machine before buying it so it fits your work area and matches the required project needs.

When planning your workspace, also think about the machine tool’s specifications and functionality. CNC machining centers, such as milling machines and lathes, often used in manufacturing, require sufficient space to accommodate their multiple axes of movement and the workpiece. The operator needs room for loading and unloading parts, as well as for auxiliary equipment like coolant systems and tool changers.

Ensuring your workspace is optimal for your CNC machine will enable high levels of production efficiency and repeatability. Machining operations, controlled by computer numerical control (CNC), allow for the creation of parts with complex shapes and high dimensional accuracy. You’ll need to invest in a robust control system, possibly one that supports AI-driven predictive maintenance, to minimize downtime and ensure the highest possible precision in your projects.

Finding the Correct CNC Control Software

CNC control software is similar to a brain, telling the machine how to turn drawing details into correct movements. The process includes making a design, preparing a toolpath with CAM software, checking the cutting path in simulation mode, and doing what's directed by G-code instructions. Selecting appropriate software, with the latest CNC software upgrades, can enhance efficiency and decrease mistakes.

CNC machines often have software that controls operations and communicates instructions to the machine. This type of software is unique to every manufacturer and model. Sometimes, these proprietary programs can only run on specific operating systems like Windows or Linux. However, not all CNC machines have their own software. Some use open-source programs or are compatible with various third-party applications for controlling and programming tasks. It's beneficial to research available software before purchasing a CNC machine because it determines what you can do with your device and how easily it will blend into your work process.

How to Choose a CNC Spindle

Knowing how to pick a CNC spindle can make a big difference in your machine's performance and the caliber of your projects. There are two main kinds: integrated spindles and attached routers.

- Integrated Spindle: These spindles usually make less noise and give steady torque over a wide speed range. They have fewer runouts, making them more precise, and they may include automatic start/stop features that can be connected with the toolpath.

- Attached Router: This is less expensive, but routers differ in torque and speed, which may affect the cut quality. It can be a good option for people with tight budgets, but they might need more manual changes.

Investing in a dedicated spindle is usually better for accuracy and steady use over time, particularly if you are working on complex or professional projects.

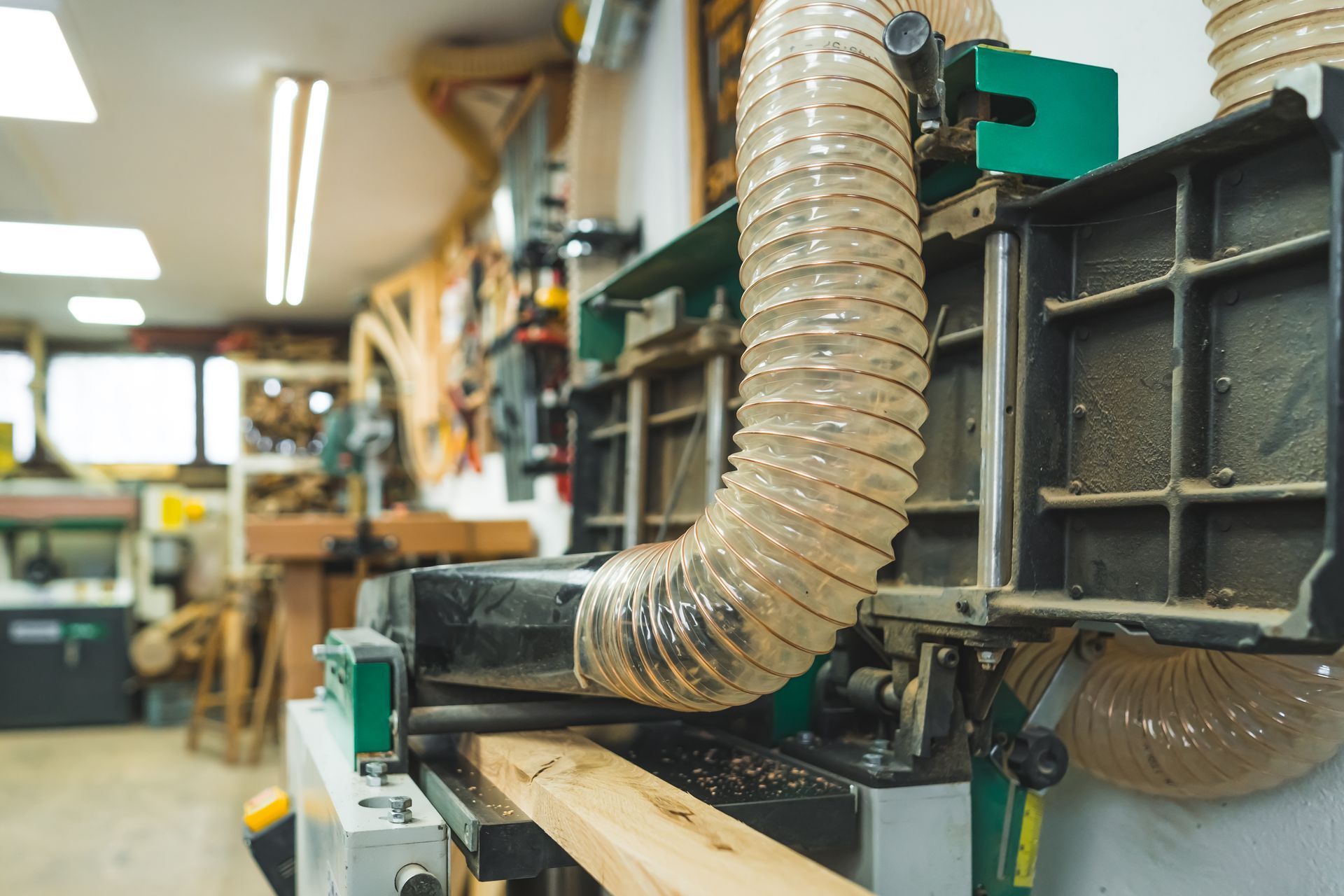

The Dirty Work: Choosing a CNC Dust Collection System

CNC machines produce a lot of dust, especially when dealing with wood. A sound CNC dust collection system is crucial for keeping the working area clean and safe. Usually, this kind of setup consists of a dust collector along with its hose and the dust shoe, which wraps around the cutting region to gather debris efficiently. In some instances, the machine might have a built-in dust collection system. However, you would need to buy this part separately.

Benefits of a Good Dust Collection System

These are some of the benefits of a good dust collection system:

- Improved Air Quality: Reduces airborne particles, ensuring a healthier workspace.

- Machine Longevity: Keeps dust from accumulating inside machinery, which can cause wear and tear.

- Clean Work Environment: Keeps your workspace clean, enhancing overall productivity and safety.

At Diversified Equipment, we assist our customers by offering them CNC systems that are integrated and customized to their particular requirements. Whether you have a small business or a large enterprise, our solutions aim to help you make the most of your production and benefits.

When selecting a CNC wood machine, you must consider your workspace, control software, spindle options, and dust collection system. Each component is crucial in ensuring that your projects are efficient and of good quality. If you want to learn more about choosing and improving the CNC wood machine for your needs, utilize our experts from Diversified Equipment. We offer full support, starting with setting up and continuing to maintain your CNC technology so you can benefit from it for a long time.

Contact us for more information on the key features of CNC machine for wood.